Trix Circus is very proud to announce that as of November 2023 we now offer fully RPEQ engineered and certified aerial hoops.

What certification did our hoops have prior to November 2023?

Up until now, our aerial hoops (and as far as we know, all other aerial hoops on the market), have not had full engineering certification. Our aerial hoops were still tested, certified and strong, however the information to assess the WLL/ULL (Weight Load Limit/User Load Limit) came from purely from NATA (National Association of Testing Authorities) destruction certification. The testing of our hoops was performed by NATA registered testing laboratories in Queensland. From the results of these tests, we made calculations to deduce appropriate ULL/WLL and Minimum Breaking Strains (MBS). This regime provided our hoops with a NATA destruction certification. This process of testing and deduction has been the industry standard.

As leaders in the circus safety industry, we have gone to the time and expense to have professional engineering certification done on our aerial hoops. The engineers at Jade Engineering and Point Engineering have calculated the MBS and points of deformation for us using both sophisticated computer programs and long-hand engineering mathematics.

From November 2023, you will have the choice to buy an Engineer Certified Aerial Hoop from Trix Circus or to purchase the older-style hoop (NATA destruction tested only) that does not come with Engineering Certification.

What does RPEQ Engineer Certification actually mean?

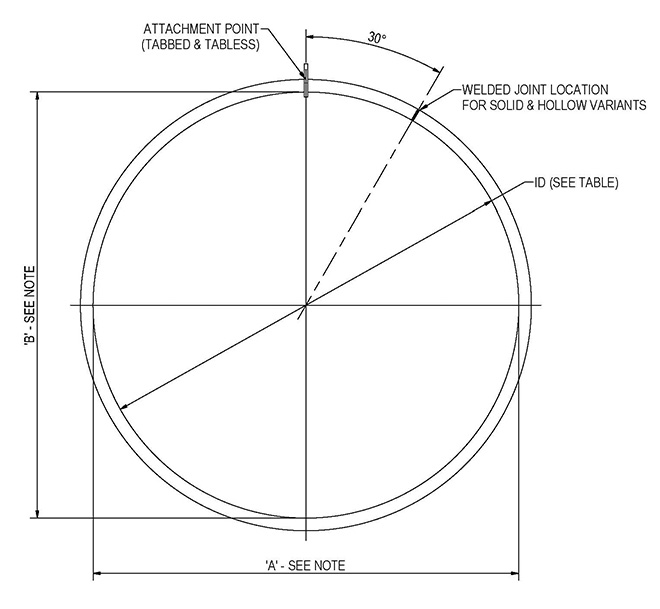

Standardisation: The engineer certified hoops will be rolled, prepared, welded and produced following very specific guidelines drawn up by the RPEQ engineers, ensuring that every hoop is produced identically and meets the appropriate Australian Standards (AS 1554.6).

Certification: As well as quality control, this engineer certification process also adds another layer of safety and surety, as we no longer need to rely solely on destruction testing to deduce the strengths and ratings of our equipment. When your studio or venue asks you for certification, what we are now able to provide is the piece of paper that they are actually asking for.

Certified and Standardized Procedures: The weld procedures which are used to fabricate the hoops are developed by an experienced Welding Specialist. The procedure is in accordance with stringent Australian Standard AS/NZS 1554.6 (this standard gives welders detailed requirements for deciding on the most effective weld size and placement in addition to how much training welding personnel need to complete the project). All personnel that weld these aerial hoops have done physical weld tests which are laboratory-certified to ensure maximum weld strength, efficiency and safety. Once each welds are completed they undergo non-destructive testing by means of a Dye Penetrant Test, which checks each weld for cracks. If any irregularities are found the weld is failed and redone by removal of weld and rewelding. All welds are 100% tested by a NATA approved testing facility.

Peace of Mind: With each engineered certified hoop, Trix Circus provides a hard copy of the engineering certification from Point Engineering. This paperwork is very important for professional performers who, as a standard, are required to show certification for their circus equipment. Studios and circus schools also often require a proof of certification to show that equipment is safe, made to Australian Standards and of the highest quality. Certification papers are now required by the majority of venues (especially government owned venues) as well as by insurance providers.

Liability: If any accidents happen in your studio, performing venue or even to a guest using your equipment in your home, you will need to have as much official documentation as possible. By completing the engineering certification process for Trix aerial hoops, we can now offer you that extra buffer against litigious claims.

Better Information: Alongside the certification papers we have issued new product data sheets on all the hoops going forward. These provide engineer-prescribed guidelines for examination, rigging and other important information. We recommend keeping a copy of the data sheet readily available, and for all coaches, owners and riggers to familiarise themselves with the information. The data sheets are always available for download on our website (https://trixcircus.com/product-info-sheets/).

Why are the engineer certified ULL and MBS different to the original NATA ones?

The engineering calculations provide theoretical numbers created through software programs and longhand mathematics. These calculations cannot and do not allow for work hardening. Work hardening occurs when the metal undergoes the bending and welding processes and it actually strengthens the final manufactured product. The engineering calculations don’t undermine the validity of our destruction tests but they do provide a definite and absolute number that the materials can be engineer certified for. This work hardening process is why our previous (NATA certified) MBS and ULL values are different from what the engineer calculations produced.

Engineer Certified MBS and ULL

| Hollow all sizes | Solid 85cm | Solid 90cm | Solid 95cm | |

|---|---|---|---|---|

| MBS | 1200kg | 2000kg | 1760kg | 1600kg |

| User Load Limit | 120kg | 200kg | 175kg | 160kg |

The above ratings are from the certification process and do not take into account the effect of work hardening from fabrication.

NATA Destruction Test Results (2021)

| Type | Destruction Result |

|---|---|

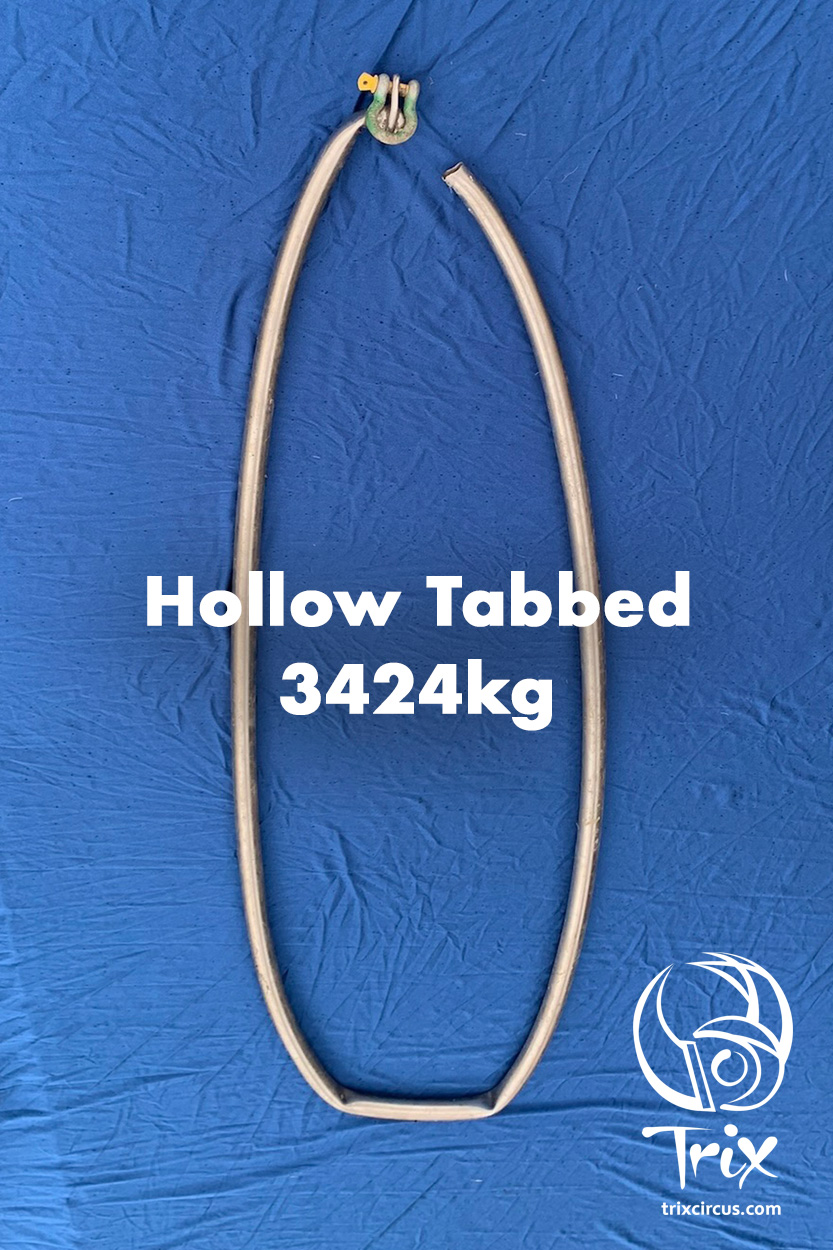

| Hollow Tabbed | 3424kg |

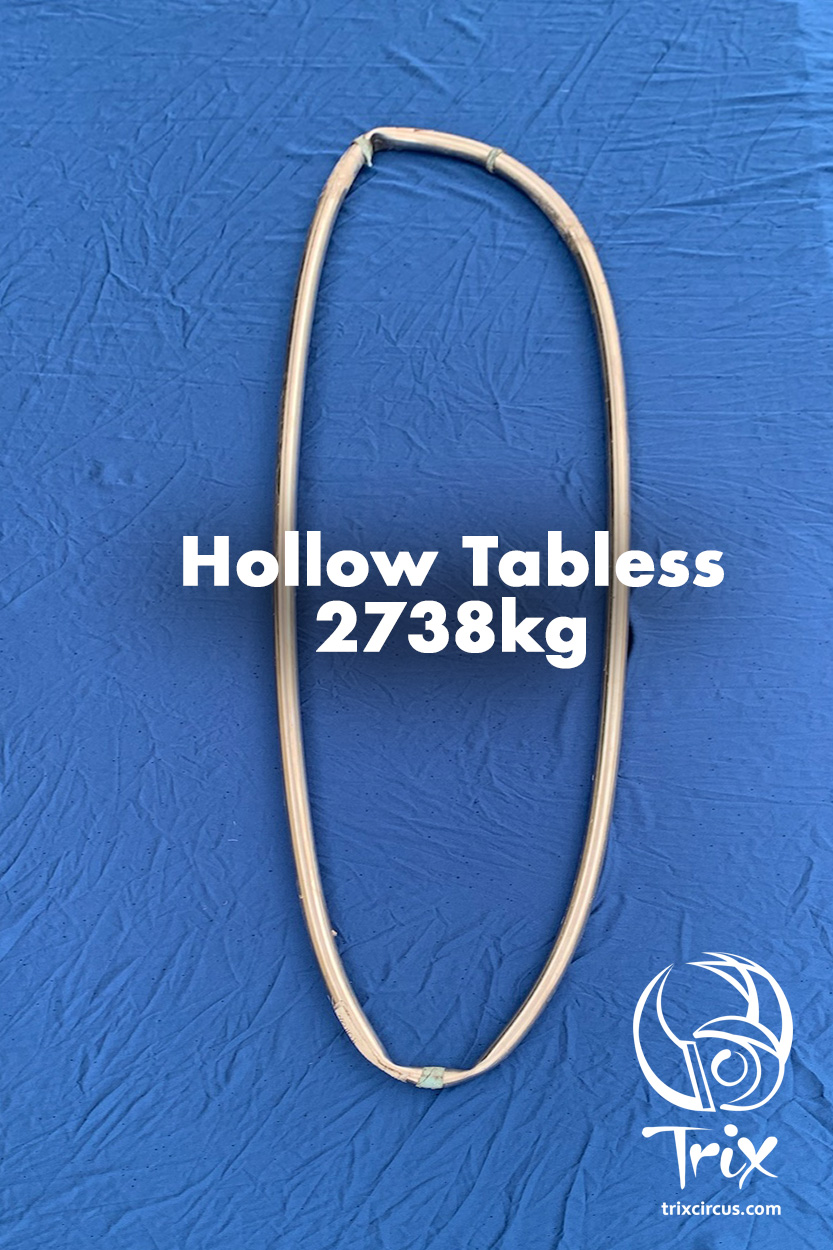

| Hollow Tabless | 2738kg |

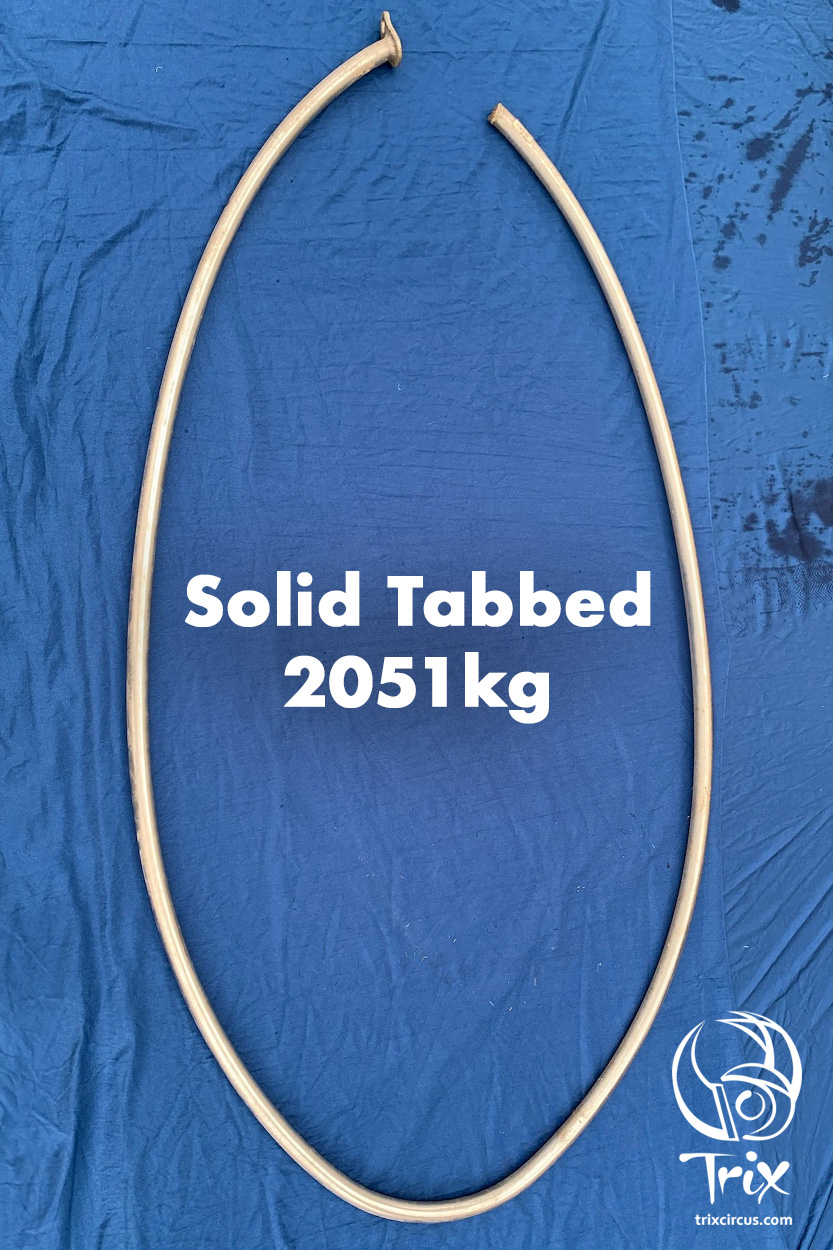

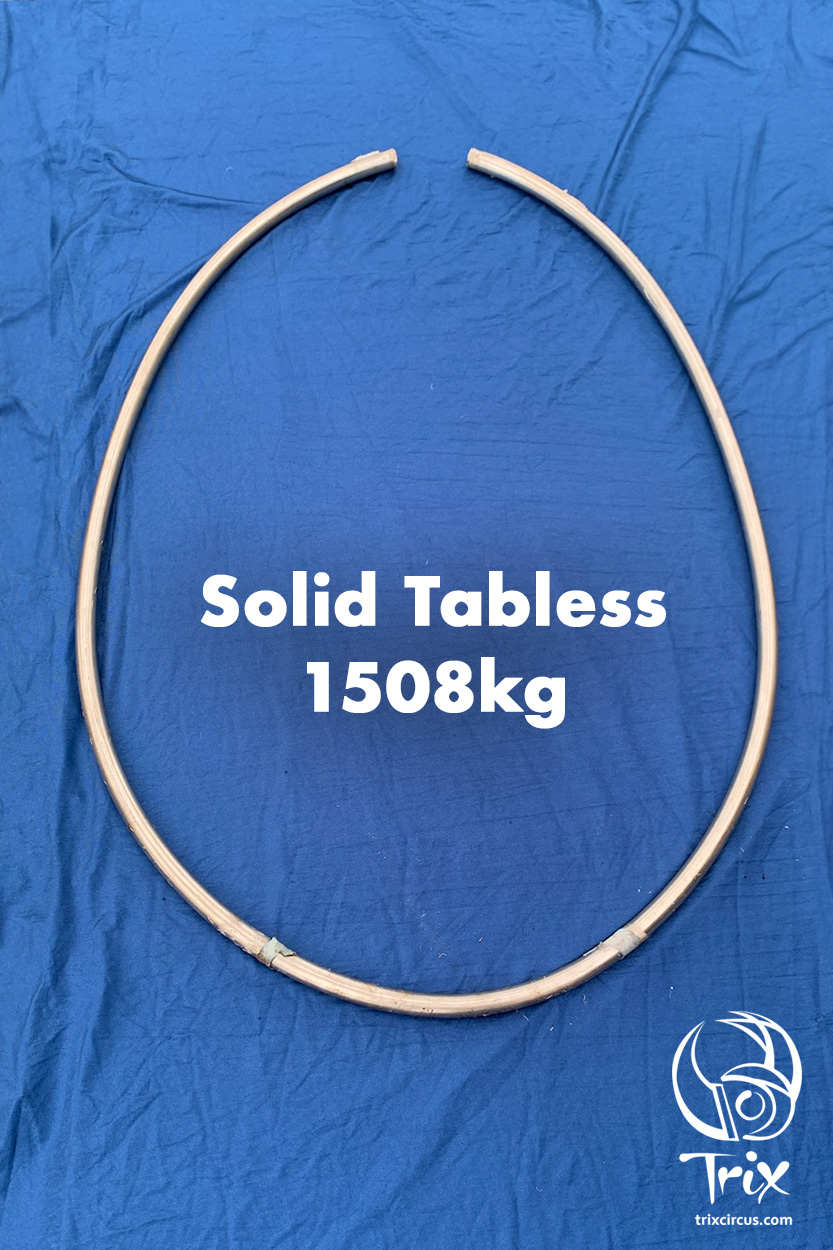

| Solid Tabbed | 2051kg |

| Solid Tabless | 1508kg |

The process of work hardening and lack of certified engineering controls is also why these NATA destruction tests varied in their results over time and between tabbed and tabless hoops.

What does this mean for Trix-brand aerial hoops without full Engineer Certification?

For Trix hoops without engineering certification, we can only provide you with the certification acquired through NATA testing. The manufacturing processes are still stringent, but they do not have the same level of engineering guidelines in place, nor do they have the same quality of welder or welding. For the Engineer Certified hoops, Trix Circus has paid for a welder to take and pass a specialised test to be proven capable of creating the specific welds demanded by the engineering certification.

Cart before Horse

NATA destruction testing is an important part of the certification process. An engineer’s calculations and certification should be the initial step, followed by the NATA destruction testing. NATA destruction certification through testing remains the pinnacle of the certification process but it should be the final stage, not the initial stage. We are now doing both of these essential manufacturing and safety protocols and offering our customers the option to buy the safest product available. Our process prior to this was the opposite of what is done in industries like construction, mining and aeronautics, where they design and engineer objects using mathematics and known quantities before testing and trialling. A little like putting “the cart before the horse”.

It’s important to note that historically, none of our previous hoops have had a failure and many of the original ones are still in use, 20+ years after manufacture. Your Trix Circus brand aerial hoop will deform very obviously well before final rupture, as witnessed in the pictures below.

Why now?

You might ask, why now? Well, our industry began as an incredibly small, very niche, smaller even than a cottage industry. Performers learnt how to weld, sew, and splice to create things they could perform on. This is how Rodleigh Stevens, director of Trix Circus and fifth generation circus artist, learnt how to create circus equipment. When he began Trix Circus, the company was solely a professional circus training organisation (we are still a professional training organisation to this day). At the time, his students found it difficult to source professional circus equipment to train and perform on, so Rodleigh used his rich knowledge from his long history in circus to make equipment for his students.

Over the past 22 plus years, the market has expanded exponentially as circus has become a recreational fitness and lifestyle choice. This seismic shift began about 5 years ago and has greatly accelerated in the past 3 and a half years. Trix Circus is now providing equipment to customers all over the world, which means we now manufacture aerial hoops in unprecedented quantities. To keep up with the growing demand, developing safety guidelines and evolving circus disciplines, Trix Circus continually updates and upgrades all our manufacturing processes. This includes introducing engineering controls where necessary. Over the past four years, we have taken each piece of our metal-based equipment through the engineer certification process, making us the only circus company in Australia to have such a large range of engineered certified products. We do this to ensure our clients – you – have the best information and safest equipment possible.

The aerial hoops are the last of our metal-based pieces with critical welds to be taken through this process. There is, of course, a price difference with the engineer-certified aerial hoops. This price difference takes into account the costs of engineering design and calculations, the costs of testing the welder, the cost of obligatory non-destructive testing and destructive testing and the higher cost of manufacturing an item to the specified engineering controls.

We understand that not every user is seeking the highest level of security whatever the price, nor does everyone needs a piece of paper certifying their equipment for use in a public space, so we will continue to offer our regular hoops as an option for our clients. We would always urge you to choose the piece that offers you the best peace of mind. Remember, aerial hoops last many many years, even decades. It is worth investing in the best version of them that you can afford. Also, when it comes to your life, you are always worth the investment.